9 Time Tracking Best Practices for US Manufacturing

“About 75% of companies are planning to accelerate their reshoring initiatives by building smart factories closer to home locations, or their customers’ point of need.” – Deloitte Insights.

Whether you are building a new facility (a greenfield approach) or upgrading an existing facility (a brownfield approach), time tracking plays a crucial role in US manufacturing operations. By implementing time tracking best practices for US manufacturing, you can make your manufacturing processes more efficient and productive.

When you have proper time tracking in place, it brings several benefits to your manufacturing operations. It can help you identify areas where time is being wasted or inefficiently used and plan your production schedules more accurately. This means you’ll be able to better meet deadlines and deliver products to customers on time.

Tip 1: Establish Clear Time Tracking Policies

Establishing clear manufacturing time tracking policies and procedures is crucial for effective time management in the manufacturing industry. By providing employees with clear guidelines, you can ensure that everyone understands how to track their time accurately. Clear policies also promote consistency and fairness across the organization.

Here are some key points to consider when establishing your time tracking policies and procedures:

- Communicate Expectations: Clearly communicate your expectations regarding time tracking to all employees. Explain why it is important and how it contributes to the overall success of the manufacturing process.

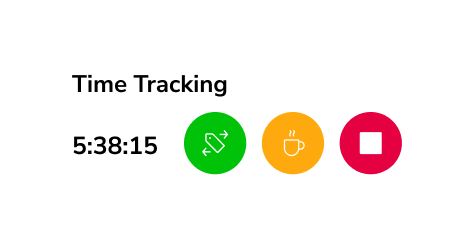

- Define Time Tracking Methods: Specify the methods and tools employees should use to track their time. This could include electronic time clocks, manufacturing time tracking software, or manual time sheets. Ensure that employees know the preferred method and any specific instructions or requirements.

- Set Time Recording Guidelines: Provide guidelines on how to record time accurately. This may include specifying shifts’ start and end times, break times, and any other relevant time entries. Encourage employees to be diligent and accurate in their time recording.

- Clarify Reporting Procedures: Clearly outline how and when employees should submit their time records. Specify the reporting deadlines and any approval processes that need to be followed. Make sure employees understand the consequences of not submitting their time records on time.

- Train and Support: Provide training and ongoing support to employees regarding time tracking policies and procedures. Offer resources, such as training sessions or user manuals, to help employees understand and navigate the manufacturing time tracking system effectively.

By establishing clear time tracking policies and procedures, you can promote transparency, accuracy, and efficiency in tracking time across your manufacturing operations. This will not only help you monitor and optimize the utilization of resources but also contribute to the overall productivity and success of your organization.

Photo by ELEVATE on Pexels

Tip 2: Choose the Best Time Tracking Software

Selecting the right manufacturing time tracking tools and software is essential for efficient time management in the manufacturing industry. By using the appropriate tools, you can streamline the process of tracking and recording time, making it easier for everyone involved. Here are some key considerations when selecting time tracking tools and software:

- Assess Your Needs: Begin by understanding your specific manufacturing time tracking requirements. Consider factors such as the size of your workforce, the complexity of your manufacturing processes, and any unique tracking needs that arise from your operations.

- Explore Available Options: Research and explore different time tracking tools and software available in the market. Look for features like user-friendly interfaces, customizable reporting, and compatibility with your existing systems.

- Consider Integration: Determine if the time tracking tools and software can integrate with other systems or software you currently use in your manufacturing operations. Seamless integration can help streamline data transfer and enhance overall efficiency.

- Evaluate Ease of Use: Look for tools and software that are intuitive and easy to use. Ensure your employees can quickly learn and adapt to the new system, minimizing disruptions to their daily workflow.

- Review Security Measures: Data security is crucial when selecting manufacturing time tracking tools and software. Verify that your chosen tools and software have robust security measures to protect sensitive employee information.

By selecting the right time tracking tools and software for your manufacturing needs, you can simplify tracking and managing time. This will enable your workforce to focus on their core tasks, enhance productivity, and ensure accurate time records for better resource allocation and decision-making.

Tip 3: Improve Attendance Tracking Accuracy with Biometric Time Clocks

In the manufacturing industry, accurate attendance tracking is essential for managing workforce productivity and ensuring smooth operations. One effective way to enhance attendance tracking accuracy is using biometric time clocks. These advanced devices use unique physical characteristics like facial recognition to identify employees and record their attendance. Here’s why biometric time clocks can benefit your US manufacturing business:

- Reliable and Accurate: Biometric time clocks provide a high level of accuracy in attendance tracking. They eliminate the possibility of time theft or buddy punching, where employees clock in for each other. With biometric technology, you can ensure that only the right employees are recorded for attendance.

- Easy and Convenient: Biometric time clocks are user-friendly and convenient for both employees and managers. Employees can quickly clock in and out using their unique biometric data, eliminating the need for physical cards or remembering passwords. Managers can easily access attendance records and generate reports for payroll and compliance purposes.

- Enhanced Security: Biometric time clocks offer an added layer of security to your manufacturing facility. Since each employee’s biometric data is unique, it is nearly impossible to manipulate or replicate, reducing the risk of unauthorized access to restricted areas.

- Time and Cost Savings: Using biometric time clocks can save time and reduce administrative tasks associated with traditional attendance tracking methods. Manual data entry and calculations are minimized, streamlining your payroll processes and freeing up valuable time for your HR personnel.

Your US manufacturing business can improve accuracy, efficiency, and security by using biometric time clocks for attendance tracking. These devices offer a reliable and convenient solution for capturing and managing attendance data, allowing you to focus on optimizing your manufacturing processes and driving productivity.

Tip 4: Train Employees on Time Tracking Processes

To ensure smooth and effective time tracking in your manufacturing operations, it’s crucial to provide proper training to your employees. You can ensure accurate and consistent tracking throughout your organization by training them on time tracking processes and how to use the software.

Start by conducting comprehensive training sessions that cover the basics of time tracking, including how to log hours, record breaks, and use the software features. Make sure to address any common challenges or questions during the training.

Additionally, provide ongoing support and resources for employees to reference whenever they need assistance with time tracking. This can include user manuals, FAQs, or dedicated support channels to address their queries or concerns.

Investing in employee training and support ensures that everyone understands the importance of time tracking and knows how to use the tools effectively. This will contribute to accurate data collection, streamlined processes, and improved efficiency in your manufacturing operations.

Tip 5: Analyze Time Data to Identify Bottlenecks

In US manufacturing, monitoring and analyzing time data can help you uncover bottlenecks and identify areas where efficiency can be improved. By closely monitoring your manufacturing time tracking data, you can make informed decisions to optimize your processes.

Start by regularly reviewing the time data collected from various stages of your manufacturing operations. Look for patterns or trends that indicate bottlenecks, such as delays or areas where productivity is lower than expected. Pay attention to tasks or processes that take longer than they should or require excessive resources.

Once you identify these bottlenecks or efficiency gaps, brainstorm solutions with your team to address them. This could involve reallocating resources, improving workflow layouts, or implementing new technologies to streamline operations. Continuously monitor the impact of these changes and make adjustments as needed.

Photo by Mark Stebnicki on Pexels

Tip 6: Implement Lean Manufacturing Principles for Time Optimization

In US manufacturing, it’s important to conduct time studies and work sampling to implement lean manufacturing principles. By using time tracking data, you can streamline your processes and eliminate waste, leading to improved efficiency and productivity.

Start by identifying and eliminating any activities or steps in your manufacturing process that don’t add value. Look for unnecessary tasks, excessive movement, or redundant processes. Simplify and standardize your workflows to minimize time wastage.

Another key aspect of lean manufacturing is ensuring an uninterrupted flow of materials and information. Arrange your workstations and equipment to promote efficient movement and easy access. Reduce waiting times and delays by establishing clear communication channels and synchronizing tasks.

Engage your team in continuous improvement efforts by encouraging their ideas and feedback. Regularly review your processes and seek opportunities for optimization. Implement visual management techniques, such as visual cues and indicators, to improve communication and decision-making.

Tip 7: Encourage Communication to Minimize Downtime

Collaboration and communication are vital in US manufacturing in reducing downtime and improving overall efficiency. By fostering a culture of teamwork and open communication, you can minimize delays and keep your operations running smoothly.

Encourage your team members to work together and share their knowledge and expertise. When different departments and individuals collaborate, they can quickly identify and address issues, leading to faster resolutions and less downtime. Encourage cross-functional teams to collaborate on projects, providing a comprehensive understanding of the manufacturing process.

Effective communication is key to avoiding misunderstandings and preventing delays. Ensure that your team members have clear instructions and guidelines for their tasks. Encourage open dialogue and regular meetings to discuss progress, challenges, and potential solutions. Use technology tools like project management software or communication platforms to facilitate efficient, real-time communication.

By fostering collaboration and communication, you create an environment where everyone works towards the same goals. This helps minimize downtime, improve problem-solving, and enhance productivity in your US manufacturing operations.

Tip 8: Connect Time Tracking with Payroll and HR Systems

“More than 63% of manufacturers report spending more than 2,000 hours per year complying with federal regulations.” from Manufacturers’ Outlook Survey: Second Quarter 2023

Time tracking is vital in ensuring compliance with labor laws and regulations. By accurately recording employee work hours and breaks, managers can demonstrate adherence to the Fair Labor Standards Act and avoid potential legal issues. Time tracking tools can generate reports that provide a comprehensive overview of employee work hours, facilitating compliance audits and paperwork.

You can simplify calculating employee hours and wages by integrating time tracking data with your payroll system. This means less manual work and fewer chances for errors. It also allows for the automatic generation of accurate paychecks, ensuring employees are paid correctly and on time.

Whether you are building new facilities from scratch or upgrading existing ones in US manufacturing, it’s important to connect your time tracking data with your payroll and HR systems. This helps streamline processes and ensure accurate and efficient employee time and wages management.

Tip 9: Use Time Tracking for Cost Analysis and Pricing Strategies

Time tracking can be valuable for conducting cost analysis and developing effective pricing strategies. By carefully tracking the time spent on different tasks and processes, you can gain insights into your production costs and make informed decisions about pricing your products.

Time tracking allows you to accurately measure the time to complete various manufacturing activities. This data helps you understand the labor costs associated with each task and identify areas where efficiencies can be improved. By analyzing the time data, you can identify bottlenecks, streamline processes, and reduce time wastage, ultimately reducing production costs.

When it comes to pricing strategies, time tracking provides you with important cost information that can guide your pricing decisions. By knowing the actual labor costs involved in producing your goods, you can set prices that ensure profitability while remaining competitive in the market. Time tracking data also helps you determine your products’ most efficient pricing structure, such as by unit, hour, or project.

To effectively use time tracking for cost analysis and pricing strategies, establish a robust time tracking system that captures accurate and detailed data. Regularly analyze the time data to identify cost-saving opportunities and adjust your pricing strategies accordingly. Consider factors such as overhead costs, material costs, and desired profit margins when setting prices based on the insights gained from time tracking.

By leveraging time tracking for cost analysis and pricing strategies, you can make informed decisions that maximize profitability and competitiveness in the US manufacturing industry. It allows you to optimize your production costs, improve pricing accuracy, and achieve better financial outcomes for your business.

Using Time Tracking for Operational Efficiency and Productivity

Throughout this article, we have explored several key time tracking best practices for US manufacturing. Implementing these time tracking best practices is crucial for US manufacturing companies to enhance operational efficiency and productivity. By establishing clear policies, utilizing effective tools, and analyzing time data, you can identify areas for improvement, streamline processes, and optimize resource allocation.

Adopting lean manufacturing principles and encouraging collaboration can minimize downtime and improve productivity. Integrating time tracking data with payroll and HR systems ensures accurate compensation and simplifies administrative tasks. Additionally, using time tracking for cost analysis and pricing strategies enables informed decision-making and enhances profitability.

Implementing these best practices can transform your manufacturing operations, maximize efficiency, and achieve better outcomes. Embrace the power of time tracking to propel your US manufacturing business to new heights of success.